Equipment

1. Material Synthesis:

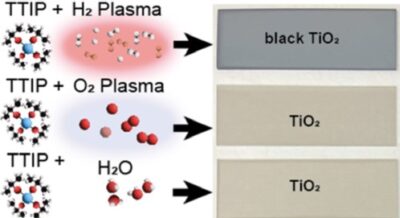

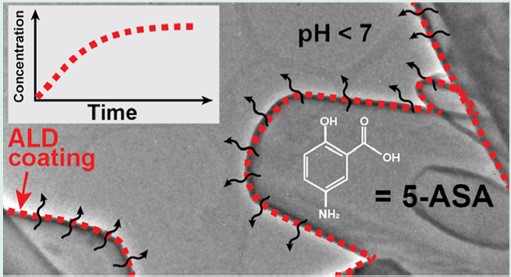

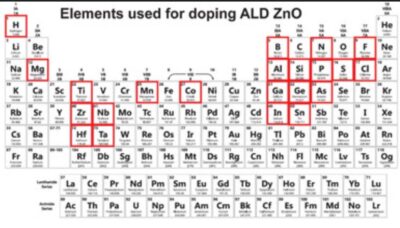

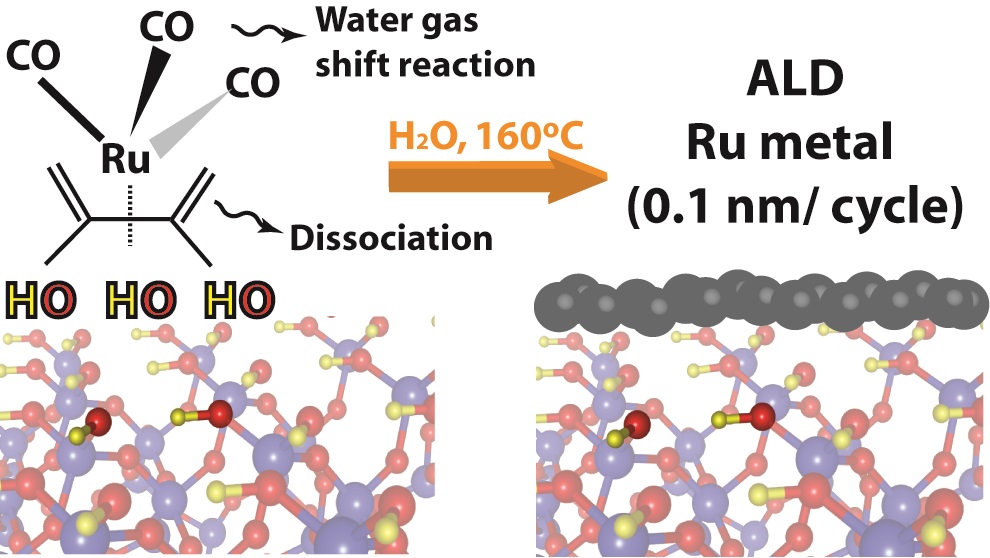

We possess extensive capabilities in atomic layer deposition / etching. The FIJI Gen2 system is an ALD / PEALD system capable of depositing on 8″ wafers. A viscous flow furnace ALD system is capable of coating 2″ substrates and powders in a barrel reactor configuration. A fluidized bed reactor (FBR) ALD system can coat powders of up to 10 gm batch sizes. All systems have in situ process diagnostics to monitor growth and chemistry of the films deposited / etched. A fully automated SILAR system i.e., the liquid version of ALD is also available and allows for quick screening of films. An electrochemical workstation (Biologic 200) provides solid-liquid interface characterization and electrochemical deposition capabilities. Table-top sputtering and viscous flow CVD reactors are available.

2. Characterization and metrology:

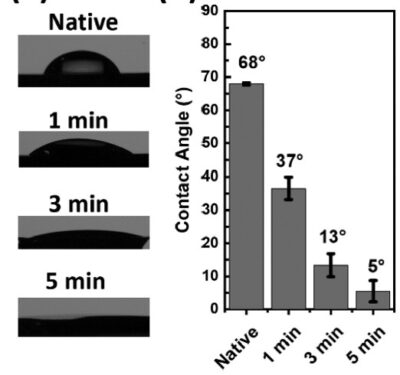

We possess cutting-edge capabilities to characterize films grown in our lab. Optical metrology is done with a Woollam M2000 spectroscopic ellipsometer, Shimadzu UV-vis spectrophotometer, and an ocean optics spectrometer coupled to an optical fiber probe. Electrical measurements are conducted on a JANIS ST500 cryogenic probe station capable of conducting temperature dependent (77K – 450K) IV, I-t, CV, photoconductance, DLTS, incident photon-to-current efficiency measurements, Hall measurements, and FET characterization. A table-top SEM / EDX provides materials, structural and elemental analysis. Two Raman microscopes (Witec and Horiba) provide necessary materials characterization. A Linkam high temperature stage (1500 C) allows for temperature-dependent measurements under the Raman microscopes. A tribometer is used to measure wear resistance of films. In line residual gas analyzers and a quartz crystal microbalance help characterize surface reactions in deposition chambers in real-time. A contact angle measurement system (Ossila) can measure surface energies of substrates.