Most people realize the climate impacts of carbon dioxide. Not many people, however, know that methane, the main component of natural gas, is much more potent than carbon dioxide.

While methane doesn’t remain in the atmosphere as long as CO2 (which can linger for thousands of years), it is 84 times more potent at trapping heat over a 20-year time horizon, according to the sixth annual assessment report of the International Panel on Climate Change. And in 2021, the emission of methane rose to record levels for the second year in a row, according to the National Oceanic and Atmospheric Administration.

That’s why UCF’s Florida Solar Energy Center (FSEC) has partnered with startup M2X Energy, which has developed a technology to capture methane from gas flare sites and convert it to liquid methanol, which can then be transported. The startup was created in 2020 and venture-funded by Breakthrough Energy Ventures, which was founded by Bill Gates and helps accelerate innovations that support getting to net-zero greenhouse gas emissions.

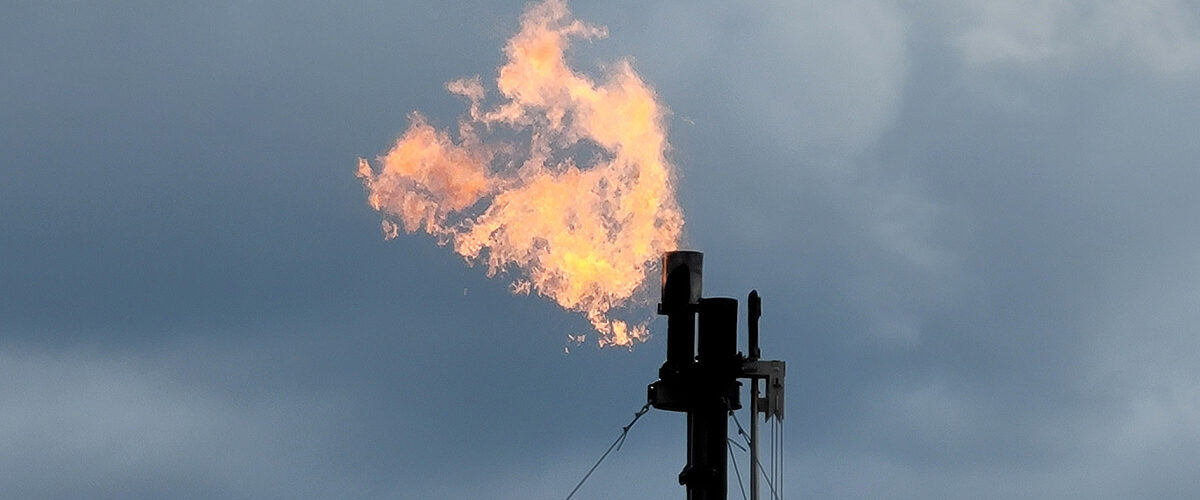

One-third of the methane emissions caused by human activity derive from the fossil fuel industry, and a significant contributor of leaking methane into the atmosphere is gas flaring. This is the process of burning and disposing stranded natural gas, a byproduct of oil production, at oil wells. With more than 16,000 flare gas sites globally, the greenhouse gas emissions equal that of all air travel.

Greenhouse gases, including methane, carbon dioxide, nitrous oxide and others, trap heat in the atmosphere and impact the Earth’s climate. These gases have risen drastically, mainly due to the increased use of fossil fuels over the past 100-plus years. An excess of greenhouse gas emissions contribute to an increase in wildfires, changes in wildlife populations and habitats, extreme weather events, rising sea levels and melting icecaps.

Gas flaring is often inefficient in practice, leaking methane in addition to producing the normal products of combustion, namely, CO2 and water.

Although the flare gas problem has been around for as long as there has been oil and gas production, and some alternatives are available, M2X Energy is bringing a first-of-a-kind, modular, transportable and scalable offering to market.

Informally known as the “plant-on-wheels”, the unit can travel to a well site and convert the gas that would otherwise be flared, on-site, to methanol, which is then transported to end users by tanker trucks.

M2X is working with FSEC to better understand and optimize the chemical processes in M2X’s modular methanol plants.

“One of the biggest challenges is making a chemical plant that can be small and still be profitable — most chemical plants are huge facilities to take advantage of economies of scale,” says Paul Yelvington, chief science officer of M2X. “Going small is commercially and technically challenging, but that’s what is required to process wellgas and stop flaring.”

Methanol liquid can be used in the production of economically viable products such as low-carbon fuels, engineered lumber, plastics, synthetic fibers, and even be used as a hydrogen carrier. A unique feature of M2X’s process is that it repurposes an automotive engine as a low-cost chemical reactor.

“These wellheads are geographically distributed, often in remote locations, and building pipeline infrastructure in order to transport gas from these isolated sources to a centralized chemical plant is economically unviable,” says Edwin Yik, principal research and development engineer at M2X. “This leads producers today to flare the, quite literally, stranded gas.”

Jim Fenton, director of FSEC, says that as one of the largest and most active state-supported renewable energy and energy efficiency research organizations in the U.S. FSEC is able to provide technical expertise and facilities in support of M2X and their mission.

“The partnership has both FSEC and M2X researchers working together, side-by-side in the same laboratory as a team to reduce emissions from stranded natural gas and make a useful product, methanol,” he says.

Nazim Muradov, the principal investigator of the project, says FSEC researchers bring to the table expertise in catalysis research, fuel reforming technology and products analysis.

“Thanks to the fruitful collaboration between FSEC researchers and M2X engineers, the project has successfully progressed to its current second phase of the technological development and has a good outlook to a prototype demonstration and introduction to the market.”

M2X Energy’s first pilot unit, which consumes approximately 85,000 cubic feet of flare gas per day and produces 5,000 barrels of methanol per year, will be ready for field demonstration in the second quarter of 2023, and the first commercial units are expected to be available for deployment in 2024.